Greenhouse climate control | How to create an optimal climate

An optimal greenhouse climate is very important and it is not particularly easy to achieve. Your greenhouse climate management has to be on point. There are multiple greenhouse climate control systems that can help you get the best climate in the greenhouse. If you have your greenhouse climate under control, it can bring several benefits such as: increased production output and yield, a higher crop quality, less waste of energy, water and nutrients and a minimum of errors by using data-driven climate computers.

In this article we have listed the most important aspects of horticulture climate control, such as air circulation and dehumidification, lighting, heating and greenhouse automation. We will tell more about how do greenhouses control climate and about what the importance of climate control in greenhouses is. Associated elements of these aspects such as temperature, humidity, CO2, moisture levels and ventilations will also be addressed. Not every greenhouse has to use the same systems to achieve an optimal climate. Therefore, if you want to optimize your greenhouse climate, it is important to know which installations and systems will fit your greenhouse and your crop. Below we will explain the most important aspects of greenhouse climate control in depth. Besides information, Hortispares also offers climate control equipment and machines!

Air treatment: air circulation and dehumidification

Air treatment consists of two aspects, air circulation and air dehumidification. On the one hand there has to be an air flow in the greenhouse, but on the other hand the air cannot be too humid.

Air circulation is an important part of climate control. The air flow in a greenhouse is very important for the quality of the crop. In a (partially) closed greenhouse the ventilation in the greenhouse is limited, causing the temperature and humidity to differ from each other. Horticulture fans can be used to keep the air flow constant and ensure that the climate is regulated.

How do I choose a type of greenhouse fan?

Choosing the right type of fan is very important. The smaller the greenhouse is, the fewer horticulture fans and different types you will need. The larger the greenhouse, the more fans you will need. This is simply because you need more variation in airflow to keep the climate balanced.

In larger greenhouses, you need more variation in air flow because there is more air and this air is heavier to move. For optimal temperature control in the greenhouse, you will need to use different types of fans: a Horizontal Air Flow (HAF) system, an exhaust system, and a vertical circulation system. A larger greenhouse has many more places where air can get trapped and therefore requires much more power to move the volume of air that is moving in the greenhouse. Hortispares offers, among others, the Priva Ecofan which creates a more evenly balanced greenhouse climate.

The benefits of greenhouse ventilation

To keep the temperature the same throughout the greenhouse, a good air distribution in the greenhouse is very important. This will prevent growth differences in the crop due to a greenhouse climate that is too hot or too cold. Among other things, greenhouse heating and ventilation systems ensure the movement of air in the greenhouse and are important for an optimal greenhouse climate. Therefore the amount of temperature, humidity, CO2, and oxygen is well distributed. In addition to ventilation systems, climate computers and screening also contribute to an optimal climate. The ventilation system is an important air support in, for example, the Enbar LVM crop protection technology. A greenhouse fan is also an essential part of the air humidification system. Placing more greenhouse fans creates an equal air movement which is ultimately better for the quality of the crop.

Drygair units

Besides the air in the greenhouse, the humidity of this air also plays a major role in the quality of the crop. Therefore besides air circulation, greenhouse dehumidification is also an important subject. But how do you control humidity in a greenhouse? Due to crop evaporation, greenhouse humidity is often too high. A classic solution for this is to open the windows by letting cold air in. The disadvantage of this is that the heating system has to maintain the temperature again and in the end this costs a lot of energy and money. The good solution is to use Drygair units. These greenhouse dehumidifiers are an efficient and easy way to dehumidify the air inside the greenhouse. This makes the air humidity and temperature more stable. Have you already bought a Drygair unit? Our specialist wrote an article about how to install a Drygair unit.

The unit is a combination of a dehumidifier and a heater. The electrical energy used and the heat released are both returned to the greenhouse. The condensed moisture is disposed of or can even be used as process water.

Advantages of Drygair units

The use of Drygair units has its advantages. The dehumidifier creates a stable humidity and temperature, reduces energy costs, prevents diseases and blemishes, reduces the need for crop protection products and ultimately creates a healthier crop due to a better climate and fewer diseases. Also, by using drygair units to dehumidify the air, there is less chance of fungi such as botrytis.

Check out air treatment spare parts per installation:

How to increase the amount of light in my greenhouse?

Sunlight is indispensable for the proper growth and development of a crop and is therefore also an important part of greenhouse climate control. Light ensures that photosynthesis can occur in a plant. Therefore, a grower usually wants to obtain as much light as possible in his greenhouse. This can be done by using assimilation lighting and LED lighting, but a cheaper way is to make optimal use of the available sunlight. In addition, care should be taken not to let too much sunlight into the greenhouse, as this can be detrimental to some crops. light thus affects the climate and temperature in the greenhouse.

LED and assimilative lighting

Sunlight is essential, but there is not always enough sunlight available. This is why many growers use assimilation lighting. Assimilation lighting are lamps that are used to supplement natural sunlight with artificial light, thereby stimulating plant growth. This ultimately leads to a better quality crop. There are various types of assimilation lamps available, but not every lamp is suitable for every crop. Different lamps are explained below. The most commonly used assimilation lamps are HID lamps or SON-T lamps, but recently LED lamps have been increasingly used in horticulture. The lamps use different techniques and are therefore suitable for different situations and applications.

HID or SON-T lamps

High Intensity Discharge (HID) lamps or SON-T lamps are assimilation lamps that use high pressure lamps. They offer a broad light spectrum and therefore can be used in all types of crops. The disadvantage of this broad light spectrum is that they also provide light that is not absorbed by the crop. As a result, some of the energy is lost.

LED assimilation lighting

LED assimilation lights are available in a broad spectrum with red, blue and white light. This allows them to provide a very specific light spectrum. Red and blue light are most important for stimulating plant growth, which is why LED lamps are more efficient for assimilation than HID or SON-T lamps. LED lights also generate little radiant heat, so the lights can be hung closer to the crop. Listed below are the different types of LED lamps:

- Growth LED: these LED lights are specifically used during the growth phase of the crop to provide additional growth light to the plants.

- Top led: these led lamps are mounted on the top of the greenhouse. This can be done next to the existing assimilation lamps, but you can also use only LED lamps.

- Interlight: these LED lamps are used as an addition to existing lighting for large crops such as tomatoes, peppers and cucumbers. The LED lamps are hung between the crops, so that the leaves that normally do not catch sunlight or assimilation light, also receive light

- Production LED: if you are growing in multiple vertical layers in a room without daylight, you can use an LED production module. These are strips that can be placed just above the crop.

- Steering light: you can use these LED lights when the crop is already a bit further in the growth and you want to influence the compactness or the flowering of the crop, for example.

Assimilation light

LED light

Shading agents

If adding lights does nothing for your greenhouse climate, shading agents might! In addition to providing the crop with extra light, for some crops it is important that the light is blocked or distributed. Many crops need “help” during sunny periods to continue growing strong and vigorous. However, while sunlight is essential for plant processes, excess sunlight in spring and summer can lead to stress and burning in some crops. To prevent this, shading agents such as chalk agent or diffusion coating is applied to the greenhouse roof during this period by means of, among others, a greenhouse chalking machine. These agents are designed to keep light and heat out of the greenhouse (chalk agent) or, on the contrary, to let in as much scattered light as possible (diffuse coating).

Shading paint for light reflection

Chalk agents reduce heat in the greenhouse by reflecting excess sunlight. This creates a more stable climate and prevents stress and damage to fruit and crops by allowing burning to occur. Peaks in the greenhouse climate are thus prevented, so the crop can be counted on to be fully protected throughout the season. Chalk coatings are used in crops that cannot withstand full sun or high temperatures.

Diffusion coatings for light transmission

A diffuse coating, on the other hand, is designed to let as much light through as possible (when it rains, the coating also becomes more transparent). Furthermore, a coating does not reflect the light, but scatters the light over a larger surface, allowing more light between and at the bottom of the crop and preventing shadowing of greenhouse stands. All this ensures that ‘more’ light enters the greenhouse and is utilized, resulting in more crop growth. In ornamental plant cultivation this results in more and longer stems and in vegetable cultivation it results in more balance and an improvement in quality and production. Royal Brinkman, a worldwide well known diffusion coatings supplier, has many types of greenhouse shading paint and diffusion coatings in its assortment. Royal Brinkman also offers other products to shade your greenhouse with, such as greenhouse shading screens.

“The more accuratly you control your greenhouse, the better your crop will grow”

Maintenance of grow lighting

More and more growers in greenhouse horticulture have a supplemental lighting installation. But the importance of maintenance is underestimated, even though it is crucial to getting the most out of it. And what’s more: delaying the maintenance can lead to unwanted breakdowns and even fire. Grow lights are extremely sensitive to external factors from the moment the installation ‘hangs’ in your greenhouse. The result: increased energy consumption, malfunctions and breakdowns, and a decline in performance and returns. Good maintenance therefore ensures maximum returns, but also safety and reliability. Below we’ve listed the main things you can do to prevent your lighting installation from malfunctioning.

- Major maintenance by the specialist

Because maintaining a supplemental lighting systems is a labor-intensive job, you can’t do labor by yourself. Moreover, the power current can be life-threatening. Therefore, it is best to have a specialist do major maintenance once a year. A logical moment to do so is during crop rotation. The crop is during crop rotation cleared out and the greenhouse is completely cleaned and disinfected.

- Cleaning by the specialist

Another component of maintenance is cleaning. Lamps, fittings and reflectors become dirty as a result of all kinds of factors and activities in the greenhouse. The light yield also decreases (by 5% within a few years) and the light also uses more energy. Dirt in reflectors can cause a decrease in reflectance value and a shortened life span. For extensive cleaning of your lighting installation you should outsource it, but you can do minor cleaning yourself.

- Check-ups by the specialist

In addition to cleaning, the specialist does a number of check-ups to determine the status of the installation, and if it needs maintenance or not.

- Self: small checks

You can prevent reduced power consumption and lower production with small checks yourself by turning on the electricity plugs a few times a year, randomly unscrew fixtures to check status and randomly check with a handheld meter how much light a bulb is still giving off.

- Self: minor maintenance work

There are also a number of minor maintenance tasks you can perform on the supplemental lighting system yourself such as checking broken lamps for the cause. For example, if the igniter keeps pulsing, this shortens the lifespan. Do the bulbs flicker? Then there may be a loose connection. This can lead to high voltage spikes and igniter failure. A lamp that goes out and comes back on when cooled is at the end of its life. In that case it should have already been replaced.

Greenhouse heating: How to get the optimal greenhouse temperature?

Besides lighting and the right air treatment, greenhouses need the right temperatures for optimal growth and production and to control the climate in the greenhouse. But how do you control the temperature in a greenhouse? Greenhouse heating solutions are therefore an important component in the greenhouse. It is important to have sufficient heating and cooling capacity in the greenhouses. For greenhouse production, you need to make sure you have enough heating capacity to handle winter conditions. Heating below the crop is usually more efficient than heating the air above the crop. Cooling capacity is also critical during the summer. Whether you use natural ventilation, fan-assisted ventilation, or pad and fan cooling, you must ensure that you can provide sufficient cooling during the hottest and sunniest weather to maintain desired grow temperatures.

To maintain the temperature, one option is to install horizontal airflow fans (HAF). Especially in indoor grow rooms, these fans are essential to help airflow distribute temperatures more evenly throughout the crop and break up microclimates around all leaves for better gas exchange. Try to avoid zones without airflow in greenhouse areas. Fans that are too high above the crop do not provide sufficient air movement in the crop. On the other hand, fans that are too close to the crop adversely affect your ability to control moisture content.

Hot air heaters

Hot air heaters can be used to heat a greenhouse. This is especially done when a complete heating system with a boiler is not financially feasible. Hot air heaters then offer a good and affordable alternative. However, it is important that you purchase the right number of hot air heaters. Tips for buying hot air heaters are given below.

Surface area of the greenhouse

Choosing a particular type of hot air heater depends on a number of factors. First, the area of the greenhouse is an important factor in choosing hot air heaters. The larger the greenhouse, the more capacity is needed to heat the greenhouse. The type of heater is chosen depending on the greenhouse section length, the number of sections and the capacity of the heater.

Delta T

The delta T is the difference between the desired temperature in the greenhouse and the minimum outside temperature. This temperature difference is important in determining how many degrees you need to heat the greenhouse with. It is also important to know whether there is an energy screen in the greenhouse, because this has an effect on the delta T. Because a screen has an insulating effect, the required heat capacity remains limited and therefore fewer heaters are needed.

Type of greenhouse

The type of greenhouse also determines the type and number of hot air heaters needed. A foil greenhouse or even a double foil greenhouse is better insulated than a glass one, which also affects the required heat capacity.

What types of greenhouse heaters are there?

Now that it is clear what to consider when choosing the right hot air heaters, it is also helpful to know what types of greenhouse heaters there are. Just like in houses, there are also different types of heating systems within greenhouses, such as central heating system in greenhouse, hot air heating or electric heating.

Central heating

In central heating, hot water is piped to the places where the heat is needed. This can be done in several ways, such as floor heating, bed heating, crop heating, greenhouse air heating and table heating.

Hot air heating

Hot air heating does not use water, but air. Warm air is blown into the greenhouse through fans by means of hot air heaters. This warm air heats the greenhouse. A disadvantage is that the heat supply cannot be accurately controlled, which makes this method of greenhouse heating not suitable for every crop. Hot air heating by means of hot air heaters is often chosen when the installation of central heating or a cogeneration system is not advantageous.

Electric heating

In some crops it is not necessary to heat the entire greenhouse. Sometimes only the bottom of the plant needs heating. In these cases, electric heating mats offer a solution. These mats only heat the specific plant pot, which is beneficial for both root growth and plant growth.

“If you take care of your greenhouse climate, the results will be worth the effort”

What are the possibilities of greenhouse automation?

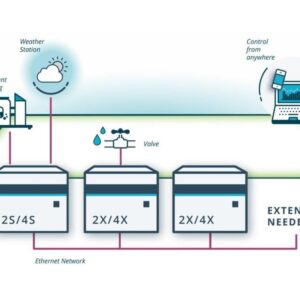

With greenhouse automation systems, you can, regardless of the type of cultivation, easily and completely control and set the greenhouse climate, the amount of light in the greenhouse, the amount of CO2 and the irrigation in your own way. These systems contribute to the most accurate possible control and management of the crop, while striving for minimal energy consumption and reuse of water. With greenhouse automation you can work more efficiently and smarter in your greenhouse. Greenhouse computer systems, sensors and more enable you to measure every little detail. The more accurately you control your greenhouse, the better your crop will grow. An example of such a greenhouse automation supplier is Priva.

Priva is a leader in supplying and producing sustainable and innovative solutions in international greenhouse farming; all with the aim of making the growth of the crop efficient. With Priva’s systems, whether you grow fruit vegetables or pot plants, you can control the greenhouse climate, the amount of light in the greenhouse, the amount of CO2 and irrigation easily and completely in your own way. These systems contribute to the most accurate possible control and management of the crop with a view to minimizing the consumption of energy and reusing water. Hortispares is one of the dealers of Priva climate and registration systems with among others process computers and climate control systems in its product range. Well known Priva process computers include the Priva climate sensor measuring box and Priva Connext, previously this was a Vocom installation.

To be able to measure all data, sensors are used. Various types of sensors which can be used to measure different types of data, are listed below. Sensors are used more and more in the horticultural sector, because they provide valuable data that you as a grower can use to optimize your crop and thus achieve higher yields.

Soil moisture sensor for potting soil

A soil moisture sensor for potting soil is meant to measure the volumetric water content (VWC) and can be used for all soil types. Using the real-time data from soil sensors, it is possible to adjust the irrigation and feeding schedule. If the crop needs irrigation or drainage, this is indicated by means of notifications. In this way you can easily prevent the harmful effects of overwatering, such as stagnant water, overheating salts, root rot, mold and mildew.

Soil moisture sensor for substrate

A substrate soil moisture sensor is designed to measure water flow, electrical conductivity and temperature in the substrate. This sensor also provides data that can be used to adjust the irrigation and feeding schedule.

Temperature sensor

A temperature sensor allows you to measure the surface temperature of the crop. This temperature can deviate from the air temperature due to various factors such as high light irradiation, cold outside air and heat radiation from tubes in the greenhouse, but can also occur at low humidity or high irradiation. By using a temperature sensor it is possible to create a temperature controlled greenhouse climate.

Temperature and humidity sensor

A temperature and humidity sensor captures real-time granular data on environmental conditions in various locations, from greenhouses to enclosed refrigerated containers.

PAR sensor

A PAR sensor measures the light intensity in the greenhouse, i.e. the power of natural sunlight. PAR light is the most important component for photosynthesis. A PAR measurement measures the light spectrum between 400 nanometers and 700 nanometers. In the case of incident sunlight, a PAR measurement can be used, for example, to provide insight into the effectiveness of a chalk or shielding agent on the greenhouse surface.

Oxygen sensor

A good oxygen level in the substrate is important for the overall root quality and the water and nutrient uptake of the roots. In addition, good oxygen levels contribute to healthier roots, which allows the plant to better defend itself against pathogenic fungi. The irrigation strategy influences these factors. With an oxygen sensor, you can measure the amount of oxygen in the substrate and thus optimize or adjust the irrigation strategy.

Point microclimate sensor (dew point).

A point microclimate sensor uses a wash temperature in combination with temperature and humidity measurements to determine VPD, dew point, humidity and temperature at the crop level. With this sensor, you can better determine heating requirements, save unnecessary energy expenses, and reduce the risk of mold and disease.

Chlorophyll fluorescence sensor

A chlorophyll fluorescence sensor provides insight into various things, such as the maturity stage of fruits like tomatoes, cucumbers, peppers or zucchini or the vigor of a crop. The sensor gives an indication of the photosynthesis activity in the fruit or leaf. In combination with other parameters such as irradiation and temperature, this gives direction for guaranteeing the quality of the fruit in the chain or identifying growth-limiting factors in the crop. This value can determine the timing of harvesting, packaging, the duration of storage and transport and the sell-by date in supermarkets, for example.

Vaporization pressure (VDP).

In addition to providing insight into the plant temperature, a plant temperature meter also provides insight into the evaporation pressure (VDP). This is the difference between the evaporation pressure in the stomata of leaves and the evaporation pressure in the greenhouse. With this, the potential evaporation of a plant can be determined (note: this is not possible for the relative humidity or moisture loss).

By measuring the plant temperature and the evaporation pressure of a plant, you can prevent overheating and condensation of plants, flowers and/or fruits when making timely adjustments to the climate conditions in the greenhouse. This ensures optimal growth with less energy consumption and it reduces the chance of mould forming in the crop.

A plant temperature meter can be connected to the greenhouse climate computer. The advantage of this is that the greenhouse climate computer can immediately and automatically adjust values (such as heating, ventilation, screening and air humidification) based on the measured plant temperature. This rapid switching ensures that the crop’s needs are met as quickly as possible. It also helps to prevent unnecessary loss of energy, CO2 and moisture.