Enbar LVM U3

Find the right part(s)

On working days your request will be handled within 24 hours by our team of specialists.

✔ Worldwide delivery

✔ Regular maintenance of horticultural machinery

✔ Hortispares is powered by Royal Brinkman

- Description

- Downlods

- Videos

- Request information

Description

The Enbar LVM (Low Volume Mist) is a product which offers optimum distribution and penetration. What’s more, the Enbar LVM is exceptionally robust and can boast long and successful use in greenhouse cultivation. The Enbar Low Volume Mist (LVM) is a space treatment device with an excellent track record in horticulture for the administration of […]

The Enbar LVM (Low Volume Mist) is a product which offers optimum distribution and penetration.

What’s more, the Enbar LVM is exceptionally robust and can boast long and successful use in greenhouse cultivation.

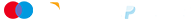

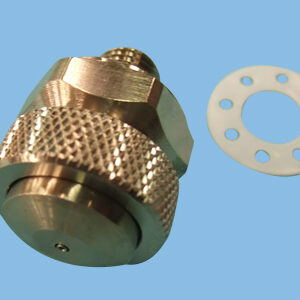

The Enbar Low Volume Mist (LVM) is a space treatment device with an excellent track record in horticulture for the administration of pesticides. In a specially developed nozzle for Enbar air is mixed with water under high pressure. This causes tiny droplets (mean droplet size 14 microns) which have a good ability to hover. The fans are spreading this mist subsiquently over the crop. Through this application technique the mist penetrates well into the crop, the mist is optimally distributed in the area and thereby means are being saved.

In a fully automatic program Enbar can treat an area, rinse pipework thoroughly and, if necessary, ventilate the area. This makes the Enbar labo- saving and reduces the necessary maintenance.

The general principle of operation is as follows. The solution tank is filled with a crop protection agent.

After the start sign has been given, the ventilator will be switched on and the compressor will ensure that the air pressure is brought to and kept at an adequate level. At the same time, the agitator mixer in the solution tank will start to rotate to keep the crop protection agent dissolved and prevent it from clumping or precipitating. The ventilator will now start pre-ventilating to start up the air stream in the treatment area. Please note that the pre-ventilation time can be set.There is a nozzle with inputs for liquids and air directly in front of the ventilator outlet. Once the atomizing (or fogging) program starts, the air valve will switch and the compressed air will exit the oxygen tank through the nozzle via the pressure regulator. This will result in negative pressure in the nozzle (the Venturi effect). This negative pressure causes the crop protection agent to be sucked up via the filter and the excess flow valve and subsequently vaporized at the nozzle head. As the nozzle is located in the air stream of the ventilator the crop protection agent is vaporized in the air stream and dispersed throughout the treatment area.The Enbar will continue to atomize the treatment area for the duration of the set time. After this, the rinse cycle will start automatically. The water valve will switch to enable the water from the rinse water tank to be vaporized. This will rinse the machine until it is clean. The rinse cycle takes approximately 3 minutes to complete. After rinsing, the post-ventilation cycle will commence (approximately 7 minutes) to ensure that any remaining droplets and moisture are dispersed.

All steps and components are controlled by a PLC (Programmable Logic Controller).

The Enbar is obtainable in a mobile version or as a unit in a fixed arrangement and with one or two units.

Specification

- Advantages of working with the ENBAR LVM:

- Optimum treatment of the area

- Easy to use

- Labour-saving

- Nobody has to be present

- Savings on plant protection products

- No visible residue on the plants

- Little maintenance, thanks to the automatic rinsing unit