Horticultural spraying equipment guide | Everything a grower needs to know about spraying equipment

With horticultural spraying equipment, also called chemical spraying equipment, you can apply chemical plant protection agents. Spraying is a technique where the pesticides that have to be applied are dissolved or suspended in water. This mixture can be applied as a mist on the crop that needs protection by horticultural sprayers. Spraying is used to control all kind of diseases, pests, and fungus on plants, but it can also be used for other purposes. Protect your crop by applying insecticides, herbicides or fungicides with (chemical) spraying equipment in order to prevent the entry of pests and diseases.

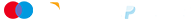

Modern horticultural sprayers are developed to maximize spraying performance and to prevent damage to the crop. Hortispares offers several types of spraying equipment: backpack sprayers, spraying trolleys, greenhouse foggers, Enbar LVM, horizontal and vertical spray booms and automatic Meto spraying robot. Horticultural sprayers are used for different kind of applications: weed killers, pesticides, disinfectants or fertilizers. Prices of plant protection equipment vary from low to high investments depending on the type of sprayer. Selecting the right sprayer depends on several factors: spray area size, spray application, fluid rate, fluid pressure, tank capacity, hose length and amount of needed nozzles. In this article, our specialist goes into detail into all topics listed below. Do you still have a question after reading the article, or beforehand? Feel free to contact us!

Navigate directly to:

- Which spraying techniques do exist?

- Advantages and disadvantages of spraying techniques

- Overview different types of spraying equipment (comparison table)

- Buying spraying equipment where to start?

- Which parts contain spraying equipment?

- Which types of nozzles do exist?

- How to choose nozzles?

- How to maintain spraying equipment?

- Spraying equipment videos

Spraying equipment spare parts

Are you looking for spare parts for spraying equipment? Hortispares is the right place for you! From parts for an Empas spraying trolley or a Pulsfog, Hortispares offers a wide range.

Which spraying techniques do exist?

There are two types of spraying you can use in the greenhouse or on the farm: low volume spraying techniques and high volume spraying techniques. It is important to know that not every spraying technique is suitable for every crop. Moreover, not every crop protection agents is suitable for every spraying technique. So, it is important to know the differences between low and high volume spraying techniques.

- Low volume spraying technique: When using a low volume spraying technique, a little amount of spray liquid is used. This spraying technique is mostly used in the cultivation of pot plants and sometimes in vegetable cultivation. Examples of low volume techniques are:

- Area treatment: means that the crop protection agent will be misted by using a Pulsfog or Enbar LVM (low volume misting).

- ULV-technique: with ULV (ultra low volume), diluting of agents is no longer required. It is possible to generate 30 million droplets from 1 ml liquid by using a rotation disc and centrifugal force. It is no longer necessary to dilute the agents. ULV ensures optimal humidification by a defined narrow droplet spectrum.

- High volume spraying technique: in contrast to a low volume spraying technique, high pressure spraying techniques use a lot a spray liquid. The water with dissolved crop protection agents is distributed by using a spraying trolley, boom sprayers and/or spray guns or lances. High pressure spraying techniques are used in floriculture as well as vegetable cultivation.

The advantages and disadvantages of different kind of spraying techniques

Every treatment has its advantages and disadvantages. Below we will sum up a few of these advantages and disadvantages of high and low volume spraying techniques you can use for your nursery or on the farm. For example, what are the advantages and disadvantages of area treatment compared to high volume techniques?

Advantages of area treatment

Area treatment has a couple of advantages:

- Less visible residue. Crop protection agents leave a visible or invisible residue behind on the crop. There is a legal standard for consumption crops: Maximum Residue Limit (MRL). This is to avoid people from ingesting harmful quantities when it is consumed. When a visible residue is left behind on the crop (fruit, flower or leaves), the (ornamental) value reduces. By using area treatment, little residue on the crop can be achieved. On the other hand, visible residue sometimes occurs when spraying crop protection products.

- Less labor required. Products can be distributed over a large surface area in a short time. With area treatment, many droplets ‘float’ through space and because of this, a better coverage of the surface of plant parts is the result. This method requires less labor than spraying because not every inch of the path of the plants needs to be sprayed. However, this type of treatment does not control pests or other diseases locally, unlike spraying.

- Less water usage. With area treatment, relatively less water is being used in contrast to spraying. Because little water is being used with area treatment, the crop dries quickly. This decreases the chance of fungal infestation.

“With area treatment you can save water by using less. This also decreases the chance of fungal infestation”

Disadvantages of area treatment

Besides advantages, area treatment also has a few disadvantages to keep in mind:

- Product only reaches the top of the leaf. If you are using the Pulsfog or Enbar LVM, the crop protection product is ‘fogged’ in the air, after which the small droplets fall on the crop. Therefore, the product only ends up on top of the leafs. Pests as white fly larvae on the underside of the leafs, cannot completely combatted with this kind of treatment.

- Differences in products. Crop protection products consists of different types, every type has its own effect. Area treatment is only suitable for products that have a contact effect.

- Short term vs. long term: A product can also have a direct contact effect. If these products are applied through area treatment, the organisms that have not been killed by direct contact are later exposed to too low concentrations in the plant. This fosters resistance. In the short term, the advantage of the more labor-friendly area treatment must not lead to the development of resistance, which means that products no longer work.

- Closed greenhouse. To make sure that an area treatment with a Pulsfog or Enbar LVM works optimally, it has to be performed in a closed greenhouse. By closing the greenhouse you ensure that the crop protection products do not end up outside of the greenhouse. It is important that the greenhouse has to be closed for a couple of hours before and after the treatment. In the summer this can be a big disadvantages, because the vents often have to be open for greenhouse climate reasons.

- Temperature is also important to pay attention to, to prevent condensation. Condensation causes dripping on leafs. During dripping, the droplets that did not dry yet, can be carried with the dripping droplets. This leads to a too high concentration of the product on the crop, which can lead to damage.

- During area treatment, no people are allowed in the greenhouse. Due to this, this type of treatment is often done in the evening or during the weekend. In large greenhouses this treatment is done with people present in the greenhouse, but in another part of the greenhouse. Always keep enough distance.

- Greenhouse fans. In order to use an Enbar LVM, you need fans to spread the mist evenly to the crop. It is important to circulate the air before and after the treatment. After spreading the product evenly through the greenhouse, the ventilators are switched off. From that moment the product has to be absorbed by the plant. If extra ventilators have to be purchased for this treatment, it can lead to more costs. But on the other hand, it also reduces labor costs.

Types of spraying equipment

Below we have listed different types of horticultural spraying equipment, such as chemical spray equipment, according to different characteristics. This overview makes it clear what the differences are between the types of spraying equipment.

| Types of spraying equipment | Birchmeier Backpack sprayer | Spraying trolley Atlanta | Spraying trolley Georgia | Pulsfog greenhouse fogger | Enbar LVM | Horizontal spray boom | Vertical spray boom | Meto spray robot |

| Application | Weeds and local pests | Crop protection | Crop protection | Area treatment / disinfection | Area treatment | Crop protection | Crop protection | Crop protection |

| Surface area | Small | Medium | Large to very large | Small to large | Medium | Medium to large | Medium to large | Medium to large |

| Cultivation* | Both | Both | Both | Indoor greenhouse | Indoor greenhouse | Both | Indoor greenhouse | Indoor greenhouse |

| Investment | Low | Medium | Medium | Medium | Medium | High | Low to high | High |

| Tank volume | 10 - 15 L | 200 - 400 L | 600 - 2000 L | 10 - 150 L | 2x 10 L | - | Depends on model | - |

| Pressure range | Max. 6 Bar | 20 -120 Bar | 20 - 120 Bar | - | 8 Bar | Depends on pump | Depends on pump | Depends on pump |

* Equipment is used in indoor as well as outdoor cultivation.

Please rotate your device to read the table on mobile.

Buying horticultural spraying equipment: where to start?

With horticultural spraying equipment, you are able to treat a large surface of the greenhouse or nursery. Spraying equipment is available in many different types and sizes, for example: chemical spray equipment. When buying horticultural spraying equipment, make sure to take a few things into account before making your choice.

Application

Before buying spraying equipment, it is important to think about the application. Think about the following questions:

- Where do you want to use your sprayer for?

- Do you just want to protect your crop to control for pests and diseases?

- Do you want to use your spraying equipment also for applying shading paint on the greenhouse?

- How frequent do you want to use your sprayer?

These questions are important to consider before buying spraying equipment. On top of that, it is important to think about which crop protection (chemical) agents you want to use.

Surface of your greenhouse

One of the most important factors is the surface of your greenhouse, because the more hectares you want to spray, the more spraying fluid you need. In large greenhouses, you should choose a large liquid tank, because this decreases the times you need to fill the tank. Spraying equipment is mostly available with spray tanks in various sizes.

The surface of your greenhouse also plays a role when choosing for a spray boom or spray gun. For larger areas, a spray boom is the best choice. A spray boom works a lot faster than a spray gun. A spray gun is more useful when spraying small surfaces or when spraying at precision.

Height of your crop

When choosing for spraying equipment in combination with a spray boom, the height of the crop is important. There are two types of spray booms: a horizontal spray boom or a vertical spray boom. With a low crop, for example in the flower cultivation and sometimes in pot plant cultivation, the horizontal spray boom is the easiest. With a high crop you can better choose the vertical spray boom, this always is with vegetable cultivation. There are also spray booms with trolleys available.

Length of the paths and the central path

The length of the paths and the main path determines how many meters of hose must be attached to the spraying equipment. This also determines how many meters of hose you need and which reel suits best. For example, with a long hose, we recommend a spring or electric reel, while with short hoses a handgun complies. It depends on the cultivation mostly. For short paths, in vegetable cultivation, a vertical boom is always used as well as an electrically driven reel. Spraying by hand is actually only done in pot plant cultivation.

Spraying fluid and pressure

Finally, you should consider what fluid you want to spray with the sprayer and what pressure it needs. The choice of pump also depends on the “pressure” the you want to spray with and the diameter and length of the hose. This is necessary in order to choose a sprayer equipped with the right pump. If you want to spray a thicker liquid and/or shading liquids, you need a sprayer with a diaphragm pump. For thinner liquids or for high-pressure treatments, it is better to choose spraying equipment with a plunger pump. The plunger pump used mostly in horticulture.

Empas parts

Hortispares offers a wide range parts for your Empas spraying equipment. Check out the whole Empas spraying equipment assortment.

Pulsfog parts

Hortispares offers a wide range parts for your Pulsfog greenhouse foggers. Check out the whole Pulsfog greenhouse foggers assortment.

Which spraying systems parts contain?

Horticultural spraying equipment consists of different parts. By intensive use of the equipment, malfunction of some parts may occur. Therefore, it is important to know which spare parts are important spraying system parts and which have a risk of breakdown. This way you can order spare parts fast if one breaks down. Of which spare parts the spraying equipment consists, depends on the type of sprayer. The major components of spraying equipment are tank, pump, agitator, flow control, and nozzles.

Agitators

Agitation is necessary to combine the components of the spray mixture uniformly and, for some formulations, to keep the pesticide in suspension. If there is insufficient agitation, the dose of the pesticide may vary as the tank is emptied. The two common types of agitation are hydraulic and mechanical. The amount of agitation required depends on the chemical used. Little agitation is needed for solutions and emulsions, but intensive agitation is needed for wettable powders.

Pumps

The pump must deliver the required flow rate to all nozzles at the desired pressure to ensure even distribution. The flow rate of the pump should be 20 percent greater than the largest flow rate required by the nozzles. When selecting a pump, take into account resistance to pesticide corrosive damage, ease of suction and availability of the power source. The materials in the pump housing and seals must be resistant to chemicals, including organic solvents. Pesticide spraying equipment usually use roller, piston, diaphragm and centrifugal pumps. Diaphragm pumps are suitable to spray thicker fluids and spray fluids with greenhouse shading paints. To spray thinner fluids or treatments where you need high pressure, please choose then for a plunger pump. Each pump has unique properties that make it well suited to particular situations. Choose a pump that best suits your crop protection strategy.

Strainers

Proper filtering of the spray mixture not only protects the working parts of the greenhouse sprayers, but also prevents misapplication due to clogging of the nozzle. Three types of sieves commonly used on greenhouse sprayers are tank fillers, liners and spray cap sieves. As the mixture moves through the system, the sieve openings must become smaller and smaller. The mesh size of the sieve is determined by the number of openings per linear inch; a high sieve number indicates smaller openings. Strainers should be checked for clogging and rinsed regularly.

Hoses

Use synthetic rubber or plastic hoses that have a burst strength greater than the peak operating pressure, are resistant to oil and solvents present in pesticides, and are weather resistant. The length of the hose is chosen after the length of the pad, a grower always orders extra meters of hose because hoses often wear harder at the beginning and end. With the extra meters growers can shorten/ repair the hose again. Spray lines should be of the correct size for the system. The suction line, which is often the cause of pressure problems, should be airtight, non-collapsible and as short as possible and have an inside diameter as large as the pump suction opening.

Pressure regulators

A pressure regulator is one of the most important parts of a spraying machine. It regulates the pressure and thus the quantity of spray material delivered by the horticultural sprayers. It protects pump seals, hoses and other spray parts from damage caused by excessive pressure and bypasses excess spray material back to the tank. There are two types of pressure regulators: simple relief valves and pressure relief valves. Relief valves are simple bypass valves that require the pump and motor to operate as if you were spraying. Pressure relief valves maintain the working pressure at the end of the system, but move the overflow back to the tank at a lower pressure, reducing the load on the motor and pump. Make sure that the flow capacity of the pressure regulator matches that of the pump in use.

Pressure gauge

A pressure gauge is essential for any sprayer systems to correctly indicate the pressure at the nozzle. The pressure has a direct influence on the delivery quantity and the distribution of the nozzles. Pressure gauges often wear out because they become clogged with solid particles of spray material. A glycerine-loaded pressure gauge is more expensive, but lasts indefinitely.

Spray boom

A spray boom is kind of robot that is able to automatically spray large areas very easily. A lot of labor can be saved by using a spray boom, in contrast to a spray gun. There are two types of horticultural boom sprayers: horizontal spray booms and vertical spray booms.

- Vertical spray booms are moving across a pipe rail system, which is between the crop. This makes this spraying technique very suitable for crops that grow upwards, such as tomatoes, cucumbers and peppers. The boom sprayer is usually attached with a pipe rail trolley. In combination with a meto spraying robot, the crop can be sprayed automatically.

- Horizontal spray booms are used in ornamentals and pot plants and spray the crop from above. This is, because there is no room for the spray boom between the plants.

Spray gun

A spraying gun is often used to spray pestcides over the crop. With a spraying trolley and spraying gun, the pesticide is evenly distributed. Spray guns are mostly used in cultivation that does not need to be sprayed often or for small areas, but is also used for specific local spraying. The most popular spraying guns are the Ripa spraying gun and the Alumax spraying gun. Both guns can be used in combination with different kind of nozzles. The nozzles are important to determine the release and spray pattern of the spray gun.

Nozzles

Nozzles are important if you work with pesticide spraying equipment, to control the volume of pesticide applied, the uniformity of application, the completeness of coverage and the degree of drift. Every spray boom or spray guns contains at least one nozzle.

Hortispares offers a wide range of parts for your horticultural spraying equipment. Make sure to prevent malfunction and buy your spraying equipment spare parts and more at hortispares.com. If you have any questions about spraying equipment or spare parts, feel free to contact us. We are happy to help you.

Exploded views

At Hortispares you can easily find the right parts through exploded views. Every machine has his own unique exploded view, which makes choosing the right spare part very easy! Just go to page of the machine you need and click the option ‘open exploded view’.

Below we have listed an example of such an exploded view. This example is of an Empas Atlanta spraying trolley and shows all the parts Hortispares offers. Just by clicking on the blue dots you will navigate to the right page so you can add the spare part to your shopping cart. Searching the right part has never been so easy!

View the exploded views map of the Empas Atlanta spraying trolley, the Empas Georgia spraying trolley and many more!

Which types of nozzles do exist?

Nozzles are an important part of spraying equipment. There are different types of nozzles available, all for different use. It is of great importance to choose the right nozzle, because nozzles determine the volume, drop size and spray pattern. If you choose the right spray nozzle, you get the best results. There are three types of nozzles where we will focus on below: Split top nozzle, Swirl nozzle and Floodjet nozzle.

Split top nozzle

Split top nozzle is used with low pressure spraying and provides an ellipse way of spraying. The nozzles are applicable for almost everything. Split nozzles has two different types, the basic split top spray nozzle and the venturi spray nozzle.

Split top nozzle is used with low pressure spraying and provides an ellipse way of spraying. The nozzles are applicable for almost everything. Split nozzles has two different types, the basic split top spray nozzle and the venturi spray nozzle.

- The basic split top spray nozzle is the most common nozzle. This spray nozzle creates a relatively small drop and provides an uniform distribution of the spraying agent in the crop.

- The venture spray nozzle provides bigger drops and these are filled with air. When the drops touch the crop, they splash into multiple smaller drops. This provides a better coverage with the spray liquid of the crop.

Swirl nozzle

Swirl spray nozzles are used with high pressure spraying and provide a cone shaped way of spraying. These nozzles produce fine drops and are therefore less suitable to attach to a spray boom because of their way of spraying. There are two types of swirl spray nozzles: a swirl spray nozzle with hollow cone and a swirl spray nozzle with full cone.

- The swirl spray nozzle with hollow cone provides small drops in a circle on the edge of the cone

pattern. - The swirl spray nozzle with full cone produces big drops in a circle.

Floodjet nozzles

Floodjet spray nozzles are used with low pressure spraying and give an ellipse way of spraying. They are suitable for big spraying volumes because of their angle of 160°. The mist of the spray nozzle contains both small and big drops. This type of nozzle is for example used by herbicides.

Because you can use different spraying equipment for control pests and diseases, it is important that you choose the right nozzles.

How to choose nozzles?

As said before, a spray nozzle converts liquid into droplets so that crop protection agents can be distributed on the crop evenly. It is important to use the right spray nozzle, as it affects the effect of the spray liquid. When choosing the right nozzle, keep the following questions in mind:

- How much liquid do I want to spray per hectare?

- Which spraying pressure do I want to use?

- Which top corner do I need?

- What type of nozzle do I want to use?

Dispensing of a nozzle

On the label of the crop protection product you can see an indication of which dissolution you are working with and in which quantity it has to be dosed onto the crop.

Nozzle pressure

The nozzle pressure depends on the desired droplets size. With a high pressure spray, you get fine droplets, while with a low pressure spray you get coarse droplets. The choice for droplet size depends on the crop protection product that you want to spray.

- Insecticides: use a coarse droplet. Because the insects move in the crop, they automatically get in contact with the droplet.

- Contact fungicides: use a fine droplet or a coarse droplet, providing that the spray liquid is evenly distributed

- Systematic fungicides: use coarse droplets, because they dry less quick. With systematic fungicides it is the aim to get as many of the active substance on the sap stream.

- Soil herbicides: use a fine or coarse droplet.

Top corner

The top corner is the angle at which liquid sprays out of the nozzle. The top angle is very important when using a spray boom. By using a nozzle with the right top angle, you ensure that each location under a spray boom gets the product from two nozzles next to each other. The spray height also has influence on this.

“When you clean your spraying equipment, make sure that the dirty water does not end up in the sewer of the surface water”

How to maintain horticultural spraying equipment?

When you are done with the crop treatments by using your spraying equipment, it is important to clean it for the next use. If you do not clean the equipment, it might occur that the crop protection products will remain in the tank. When you use the tank without cleaning it, there is a chance that you will get crop damage. Shortly, always clean horticultural spray equipment or your spraying trolley after usage!

The importance of cleaning a spraying trolley

Not only is cleaning of spraying equipment or a spraying trolley important, it also has advantages. It is necessary so that the crop care sprayer is functioning well. It also prevents damage to the crop because the residue of the products will not end up in the crop. With cleaning, you also prevent unintentional contamination, which occurs when two substances that cannot get in touch with each other, get in touch.

Removal of residual liquid

It can occur that there is left residue of the crop protection product in the tank. This happens when you have mixed too much liquid. Never discharge the spray liquid into surface water or the sewage system.

External cleaning

Externally cleaning of a spraying trolley takes little time and water. Use a spray lance that is connected to a source of clean water to clean the outside of the spraying trolley. Make sure that the dirty water does not end up in the sewer or surface water.

Internal cleaning

By filling the tank with clean water, you can clean the pumps, pipes and nozzles and thus the whole interior of the spraying trolley. Use a spray gun that can spray clean water under high pressure. To get the best results, use detergent. Keep the following method in mind when using detergent:

- Rinse the spraying trolley with water.

- Refill the tank with approximately 10-20% of the total volume with water.

- Add detergent and pump the mixture through the system for about 15 minutes.

- Empty the tank completely.

Personal protective equipment

When cleaning crop care spraying equipment or a spraying trolley, always wear personal protective equipment.

Spraying equipment videos

On the YouTube account of Royal Brinkman you can find more videos about, among others, maintaining en cleaning horticultural spray equipment.