Pulsfog

PulsFOG spare parts for horticulture

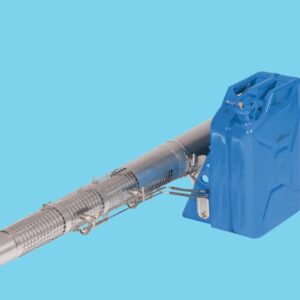

Pulsfog foggers are used by spraying pesticides in greenhouse to prevent crop damage. To protect crops, growers use horticultural spraying equipment to apply chemical and biological crop protection products to the crop. In horticulture two kinds of spraying techniques are used: low-volume and high-volume spraying equipment. Sometimes it is needed to treat a specific area, therefore growers do an area treatment with low-volume spraying techniques, such as a thermal fogger. In case of high-volume spraying equipment, spraying trolleys, spray booms and spray robots are used to apply pesticides to the crop. Would you like to know which spraying equipment fits your situation? Please read our full guide about spraying equipment.

A PulsFOG greenhouse fogger is part of this low-volume spraying technique. PulsFOG is well-known for its high-quality well-known greenhouse foggers to apply disinfectants and pesticides. PulsFOG foggers are available in different types: K4, K10, K30 and Bio version. At Hortispares you can find all spare parts for the several PulsFOG types.

What is thermal fogging?

Thermal fogging is producing ultra-fine droplets in a range of 1-50 µm. This is possible using thermopneumatic energy. At the end of the fogging barrel, liquid substances are vaporized. These evaporated liquid substances form ultrafine aerosols due to condensation upon contact with cool ambient air, upon ejection, creating dense visible fog clouds. Pure oil solutions or aqueous liquids with a glycol component are especially suitable for this purpose.

Thermal spraying is often used when active substances need to be uniformly distributed, for example in pest control. Thermal fogging actually ensures that even in inaccessible places, without leaving undesirable residues, the substances are distributed.

The operation of a PulsFOG

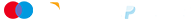

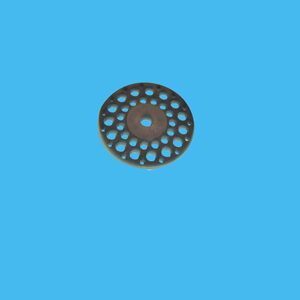

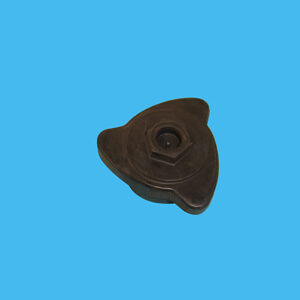

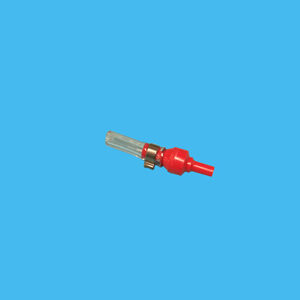

A PulsFOG fogger is equipped with several important components: pulse jet engine, spark plug, chemical liquid tank, jet nozzles, start-carburetor, fuel tank and more. It is important to maintain the fogger regularly to prevent standstill or malfunction. However, next to maintenance it is even more important to clean the greenhouse fogger after use. In this way, you prevent remaining crop protection agents in the fogger causing crop damage when using next time. In this blog you can read about how to maintain a Pulsfog.

For instance, it is important to remove the chemical tank and rinse it with water and a few droplets of detergents. Furthermore, it is important to clean the diaphragms of the carburetor. However, it can occur that the hoses of the PulsFOG leak. In this case, you should replace the hoses of the fogger. Jet nozzles can contain dirt causing unevenly application of crop protection agents.

Broken greenhouse fogger spare parts

Sometimes your fogging machine occurs faults, broken component or other problems. Therefore, it is important to have the right replacements parts in stock. When the jet nozzle contains dirt, you can remove it with a steel brush. At Hortispares you can also find hoses, membranes, nipples, carburetor and more.

Find the right spare parts easily

Are parts of the PulsFOG in need of replacement? Hortispares supplies different parts for different PulsFOG machines such as the K22, the K10 and the K4. Is the petrol nozzle of the K10 in need of replacement? Or does the pressure gauge of the K22 need to be replaced? Order all parts easily and directly at Hortispares. Do you have any questions about a product or do you need help? Please feel free to contact us. With worldwide shipping and secure payment methods, growers and technical installers all over the world are able to safely buy the right spare parts.