- Description

- Downloads

- Request information

Description

Advantages of the UdiMatic: The UdiMatic, an automatically self-cleaning filter, offers an efficient solution to filtration at a minimal loss of pressure and flushing water. The self-cleaning system sucks the deposited dirt/waste from the filter screen in approx. 8 seconds, while not interrupting the filtering process. The filter element composed of stainless steel filtering layers […]

Advantages of the UdiMatic:

The UdiMatic, an automatically self-cleaning filter, offers an efficient solution to filtration at a minimal loss of pressure and flushing water.

The self-cleaning system sucks the deposited dirt/waste from the filter screen in approx. 8 seconds, while not interrupting the filtering process.

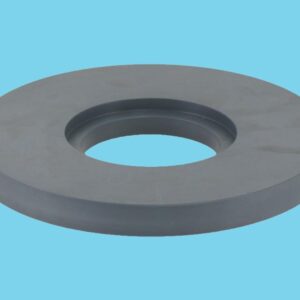

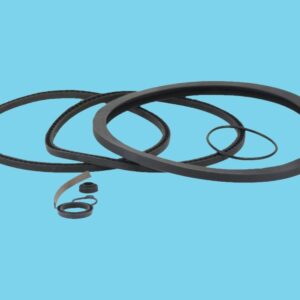

The filter element composed of stainless steel filtering layers sintered to one another has an extremely effective filtering surface. Equipped with maximum differential-pressure protection, a controller box with a flushing programme and an electrically operated drain valve, the filter is supplied ‘ready to be plugged in’.

The UdiMatic is a complete automatic filter for use in a wide range of installations.

The UdiMatic, a mid-sized automatically self-cleaning, electric screen filter, is available in 1”, 1½”, 2”, 3”, 4”, 6”, and 8”; It has a flange connection (1”: thread) and is made of polyester-coated steel with a maximum working pressure of 10 bar.

Coating:

In preparation for the coating, the filters are provided with a special layer of zinc phosphate. This treatment ensures proper adhesion of the coating, and protects against rusting-through from the inside. Subsequently, the polyester coating is applied electrostatically, both internally and externally, before being furnacehardened. The entire process involves 7 steps, and results in a perfect coating with a thickness of approximately 120 microns.

Applications:

• Process water

• Cooling water processes

• Recirculation systems

• Irrigation systems