UDI Circulation filter 2″

- Description

- Downloads

- Request information

Description

Advantages of circulation filtration Separation of the dirt from the water using flow energy. Large dirtdischarging capacity at minimal loss of flushing water. Well-adjusted inflow keeps the filter element clean. Advantages of UDI circulation filters: Strong steel with resistant plastic provide a filter which is suitable for many purposes. A high working pressure (max. 8 […]

Advantages of circulation filtration

Separation of the dirt from the water using flow energy. Large dirtdischarging capacity at minimal loss of flushing water. Well-adjusted inflow keeps the filter element clean.

Advantages of UDI circulation filters:

- Strong steel with resistant plastic provide a filter which is suitable for many purposes. A high working pressure (max. 8 bar) poses no problem.

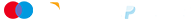

- The UDI circulation filter has a PVC filter element with a stainless steel filter mesh of 75 to 800 microns.

- By removing or adding plugs, the flow velocity can be optimised.

- Discharging dirt can be automated in a simple manner.

- To increase the dirt-discharging capacity, the filter can be applied crossflow.

- All models can be modularly interconnected to form units of any shape and capacity, if necessary with a joint dirt-discharge tank.

- A comprehensive range of fittings, connectors, and rapid couplings of the same make is available for assembling the units.

- A stainless steel version of the filter is optionally available. The largest models are available with a pre-filter to capture large particles(stone trap).

Coating

In preparation for the coating, the filters are provided with a special layer of zinc phosphate. This treatment ensures proper adhesion of the coating, and protects against rusting-through from the inside. Subsequently, the polyester coating is applied electrostatically, both internally and externally, before being furnace-hardened. The entire process involves 7 steps, and results in a perfect coating with a thickness of approximately 120 microns.

Model

In-line, the filter body pointing downwards.

Applications

- Recirculation systems

- Cooling water processes

- Washing-/flushing water purification

- Basin water filtration

- Irrigation systems

Materials

- Polyester-coated steel

- Neoprene rubbers

- Nylon whirl plate

- PVC filter element with stainless steel filter screen

- Perforation: 75, 100, 130, 200, 300, 435, and 800 microns (other perforations upon request)