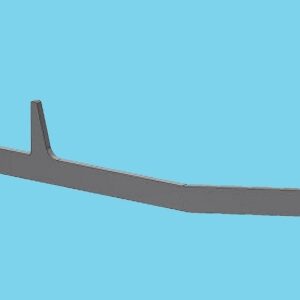

Super Bio Chopper Compact HFC92 crop shredder

- Description

- Technical specifications

- Videos

- Request information

Description

The Super Bio Chopper Compact, from Weterings Machinery, is ideally suitable for shredding vegetable plants and crops in horticulture. The main difference between the Super Chopper and the Bio Chopper compact is that the Super Chopper offers 40% more horsepower (HP’s). This ability translates into extra speed, so that the clean out time is even […]

The Super Bio Chopper Compact, from Weterings Machinery, is ideally suitable for shredding vegetable plants and crops in horticulture. The main difference between the Super Chopper and the Bio Chopper compact is that the Super Chopper offers 40% more horsepower (HP’s). This ability translates into extra speed, so that the clean out time is even further reduced. So, for greenhouses with heavy tomato and peppers crops the Super Chopper Compact will be the best solution.

Shredding different kind of greenhouse crops

The Super Chopper Compact shredder is worldwide used during crop rotation of tomatoes, peppers, cucumbers, eggplants, strawberries, raspberries and blueberries. With shredding plants the crop volume is reduced to about 20% of the original volume. In this way, you are saving a lot of space in terms of waste disposal. A crop shredder operates well in small as well as large greenhouses.

Operation of the Super Chopper Compact

The Super Chopper Compact is easy to operate and maintain. This crop rotation machine is built according to the latest safety standards and has capacity of approximately 2500-6500 m2/hour (depending on the logistical conditions). It’s compact dimensions make this machine ideal for narrow situations. By using ground cloths and attach it to the machine, the ground cloth will be pulled towards the shredder. The crop is dropped on the ground cloths. Then the crop goes into the shredder, after which the ground cloth is rolled up again. Use the shredder in combination with a buffer and tipping container. The crop waste then ends up in these containers. When the container is full, the waste can be discharged in a large waste container.

| HW-number | 0751855 | Gauge (mm) | 1370 |

| Length in transport position (mm) | 2530 (with slewable discharge unit) | Width tracks (mm) | 230 |

| Width in transport position (mm) | 2181 | Ground clearance (mm) | 200 |

| Height in transport position (mm) | 2397 (with slewable discharge unit) | Ground pressure tracks (gr/cm2) | 540 |

| Wheel base (mm) | 1307 | Own weight (kg) | 3250 |

| Max. drive speed (km/u) | 2.1 (normal mode) / 3.8 (fast mode) | ||

| Shredding capacity (m2/u) | 2500-6500 (depending on circumstances) | ||

| Max. length of transport mat (m) | 200 | ||

| Diesel engine | John Deere 4045HFC92 (86 kW) |

How to start up and drive a Bio Chopper

How to sharpen the cutting blades of a Bio Chopper